INDUSTRIAL JP

idstr.jp open shareNovember 1, 2021

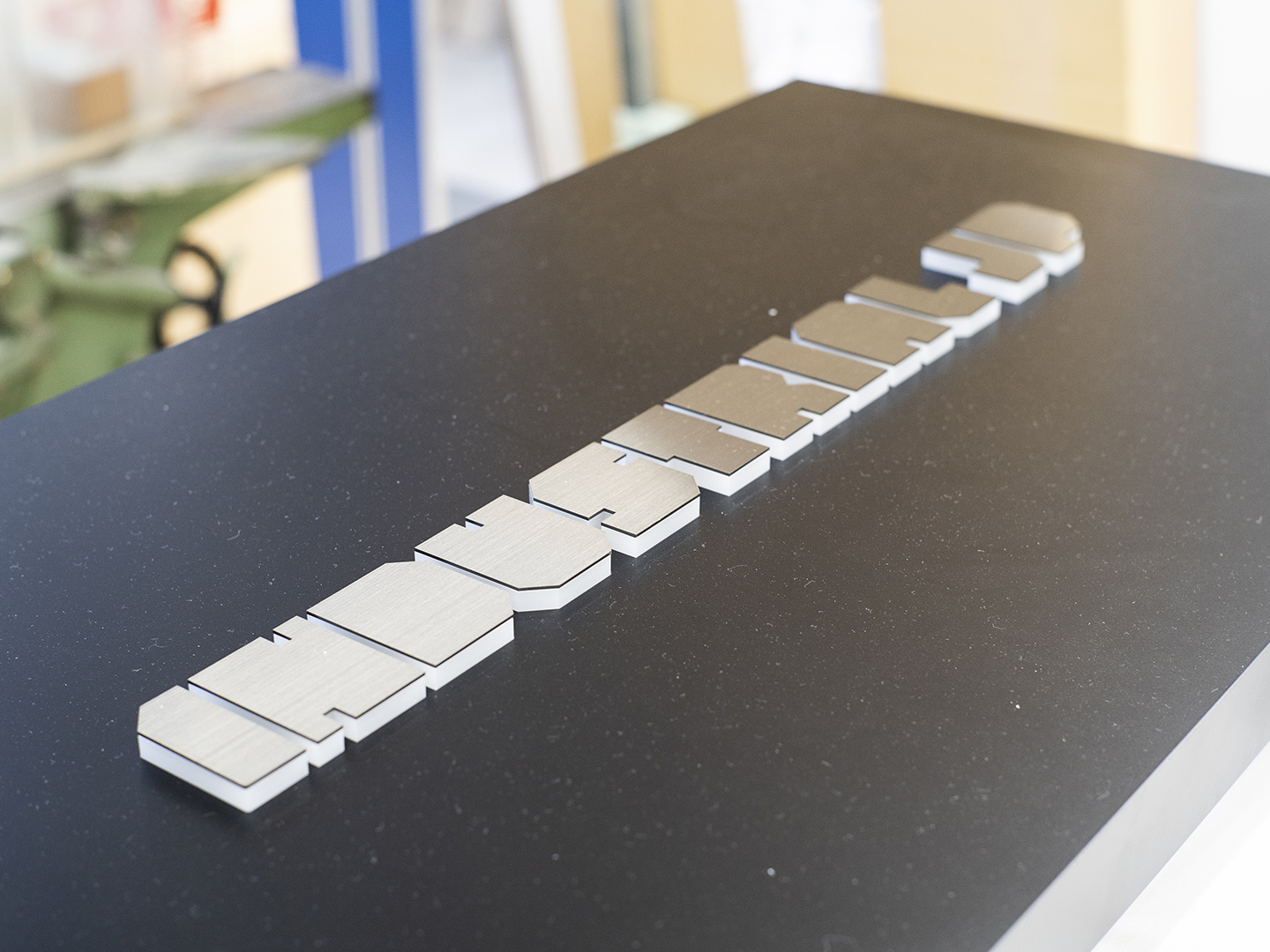

AT-13

omino

interview

Experience opens the way to new destinations.

// omino interview

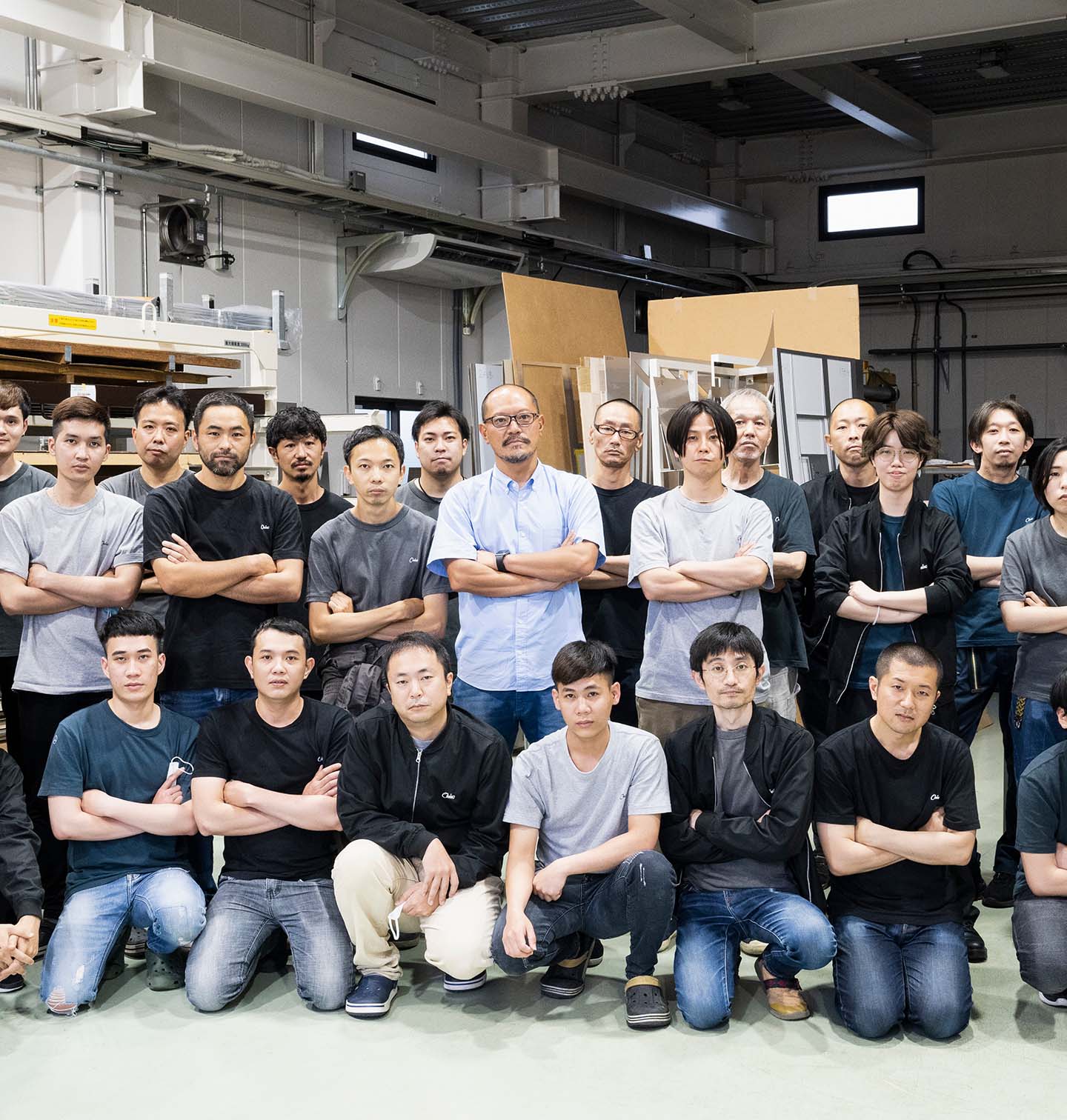

Omino Co., Ltd. is engaged in the manufacture and sale of all manner of signs made using LEDs, resins like ABS and acrylic, metal, and more. At their factory in the city of Yashio in Saitama Prefecture, the company produces a stunning variety of signs, from extravagant logos for designer brands to elegant billboards and displays for office buildings. We talked to them about how they managed to build their reputation as the sign professionals.

oomino sign

ID-13

omino

takecha

The winning sign company is the one that figures out how to finish in time for opening day.

I understand that Omino produces signs for famous fashion brands, hotels, office buildings and more. The arrows that repeatedly show up in the music video left a strong impression. Are they a kind of sign as well?

Narumi, Director, Production Department : When you hear the word “sign”, you might imagine an old-fashioned galvanized iron sign with a store name painted on it, or the brand logo for a store hanging from a storefront. But signs can show you everything, from the direction to the nearest washroom in a shopping center, to the direction you need to go to get to your destination. Here at Omino, we make all those signs and more.

That is why our customer base is primarily made up of companies involved in facility design, general contractors, and interior and exterior signage companies. We usually receive manufacturing orders when a new store, company office, or residential building is completed, along with blueprints from the customers for the signs they need, for example entrances, exits, and in store displays. Customers often to ask us to give them something that is unique. They spend their time searching for a company that can do what they want, and in the end, they come to Omino because they know we can achieve what they’re looking for.

So, you aren’t mass-producing signs to meet certain specifications, you specialize in small-lot jobs, and high-mix, built-to-order manufacturing.

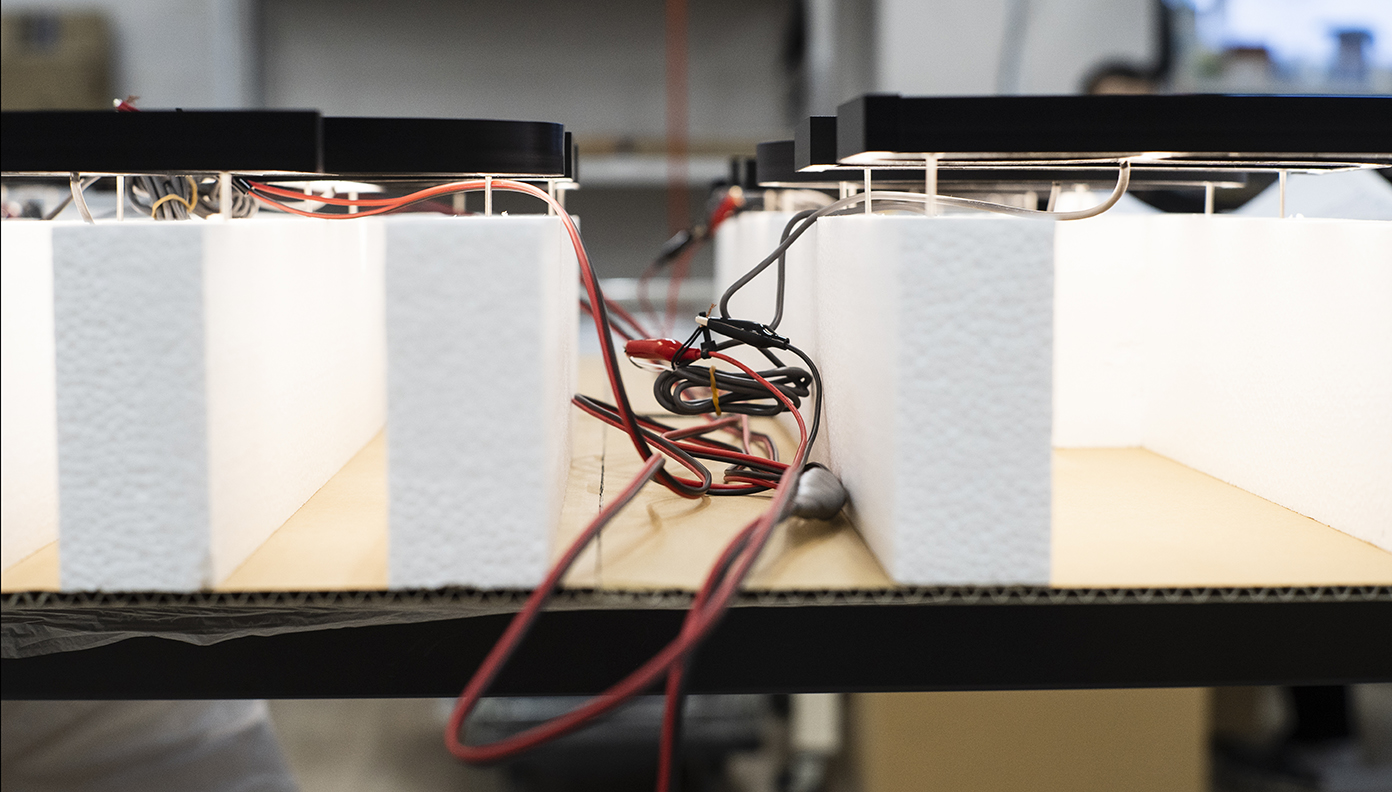

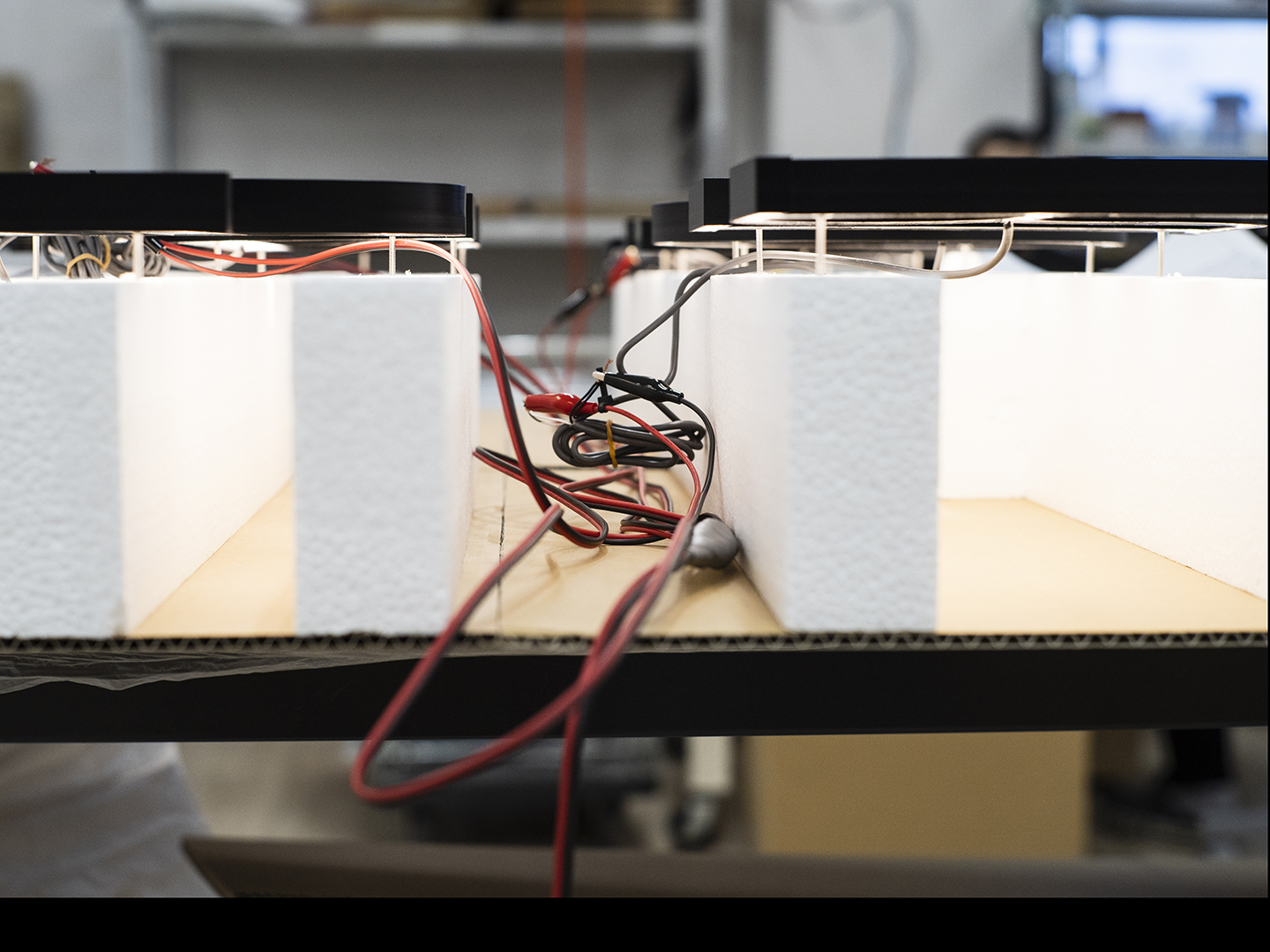

Narumi: Exactly. We primarily work in making signs based on the blueprints we are given. However, that doesn’t necessarily mean that we follow the customer’s instructions to the letter. For example, sometimes we’ll receive a drawing for an LED sign where the logo is too narrow for the sign to fit the needed LEDs, or perhaps their designer won’t have left enough space to run electrical wiring. One of our jobs is to adjust the design to make sure that the sign works properly when it’s installed on site.

How long does it take to complete one sign?

It usually takes between one and three weeks to complete a single order. It depends on the material we will be using and on what finishing touches are needed. We have managed to gradually shorten the work process through competition with other companies. Stores are also being opened at a faster rate than in the past, so the winning sign company is the one that figures out how to finish in time for opening day.

The work is split between around 40 employees, and everyone is always thinking about how to do each step of the process in the most efficient way. We are always trying to determine the optimal solution as we put in the effort to create a sign that will satisfy the customer.

That’s faster than I expected! How about the sign you made for the INDUSTRIAL JP music video? About how long did that take?

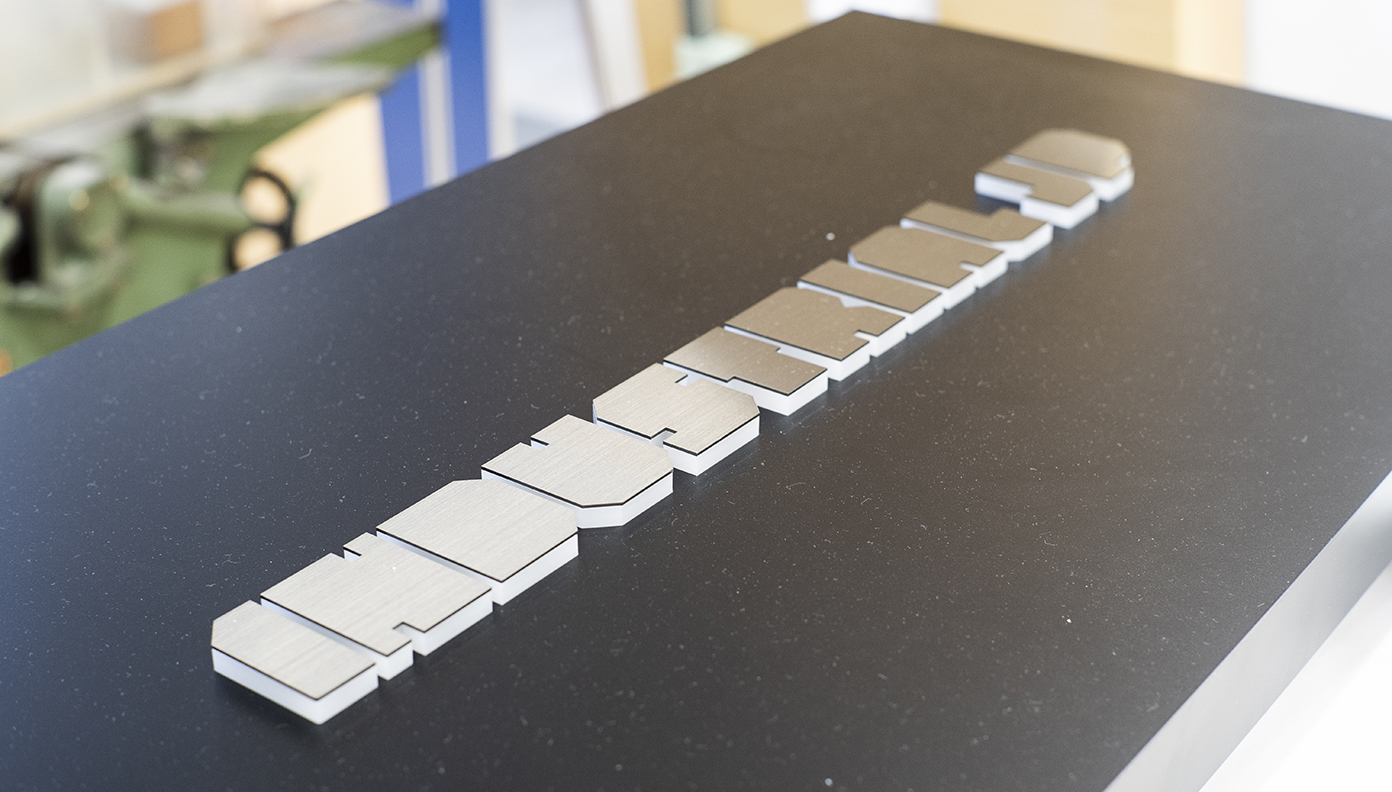

The INDUSTRIAL JP sign took about two weeks. It used black nickel plating, but if it had been gold plating, I think it might have taken longer. It was relatively simple.

Do you also make your own original products?

Narumi: We make some for use in-house when we’re trying new technologies, but that’s about it. We are not in product sales, and we don’t have an in-house designer who can create original products. For the INDUSTRIAL JP sign, we received a 2D drawing and then we handled the structural design needed to make it 3D.

Each person’s experience,

the work they’ve done in the past,

is reflected in the process they use.

For the video, we captured the various processes you use on film, from cutting to painting, but do you use any unique knowledge or special technologies in your work?

Narumi: Actually, each approach is different and depends on the person in charge of doing the work. In the video, you see a sign being cut using an NC router (a machine that cuts material using a blade). If you give the exact same design drawing to many different employees, each person will use a blade of a different type or thickness when they cut out the curved lines and straight lines for the lettering. However, the resulting sign will be exactly the same, no matter who makes it.

Each person’s experience, the work they’ve done in the past, is reflected in the process they use.

Tsuchida, Machining Group Leader: Cutting is a process that requires judgement. Maybe one piece needs a thick blade to get through the stock, maybe another needs a thinner blade to make sure we get all the detail. It’s scary because once you turn on the machine, you don’t get a do-over.

These machines are operated by loading a machining program into them, but if the program is even a little bit off, we have to start over from the beginning. And we can’t just think about it as learning from our mistakes. Most of our projects have to be completed first try, from the perspective of budget and lead time. We only get one chance with the laser cutter as well. That being said, as you gain more experience, you get faster at figuring out the best way to get the job done. Getting used to the machines is a very important process too.

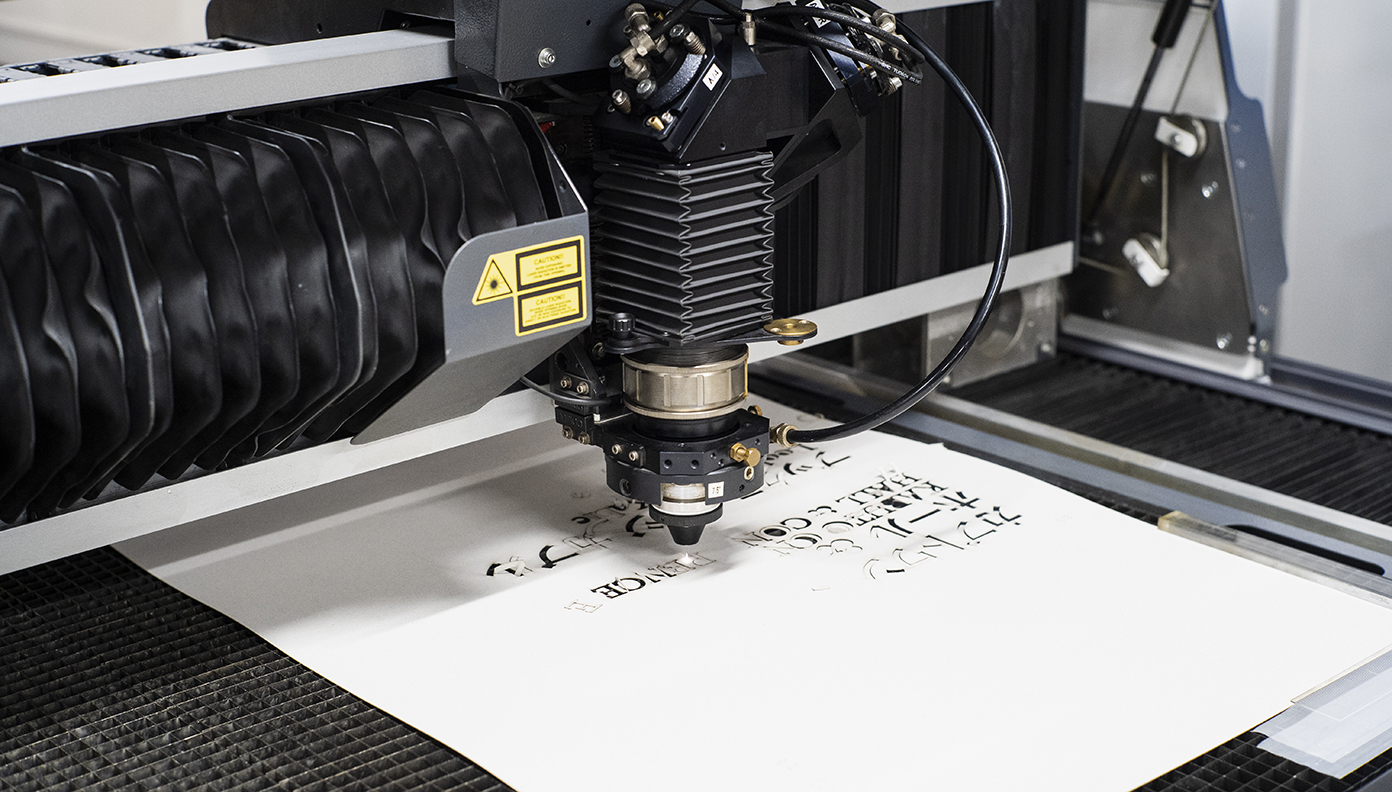

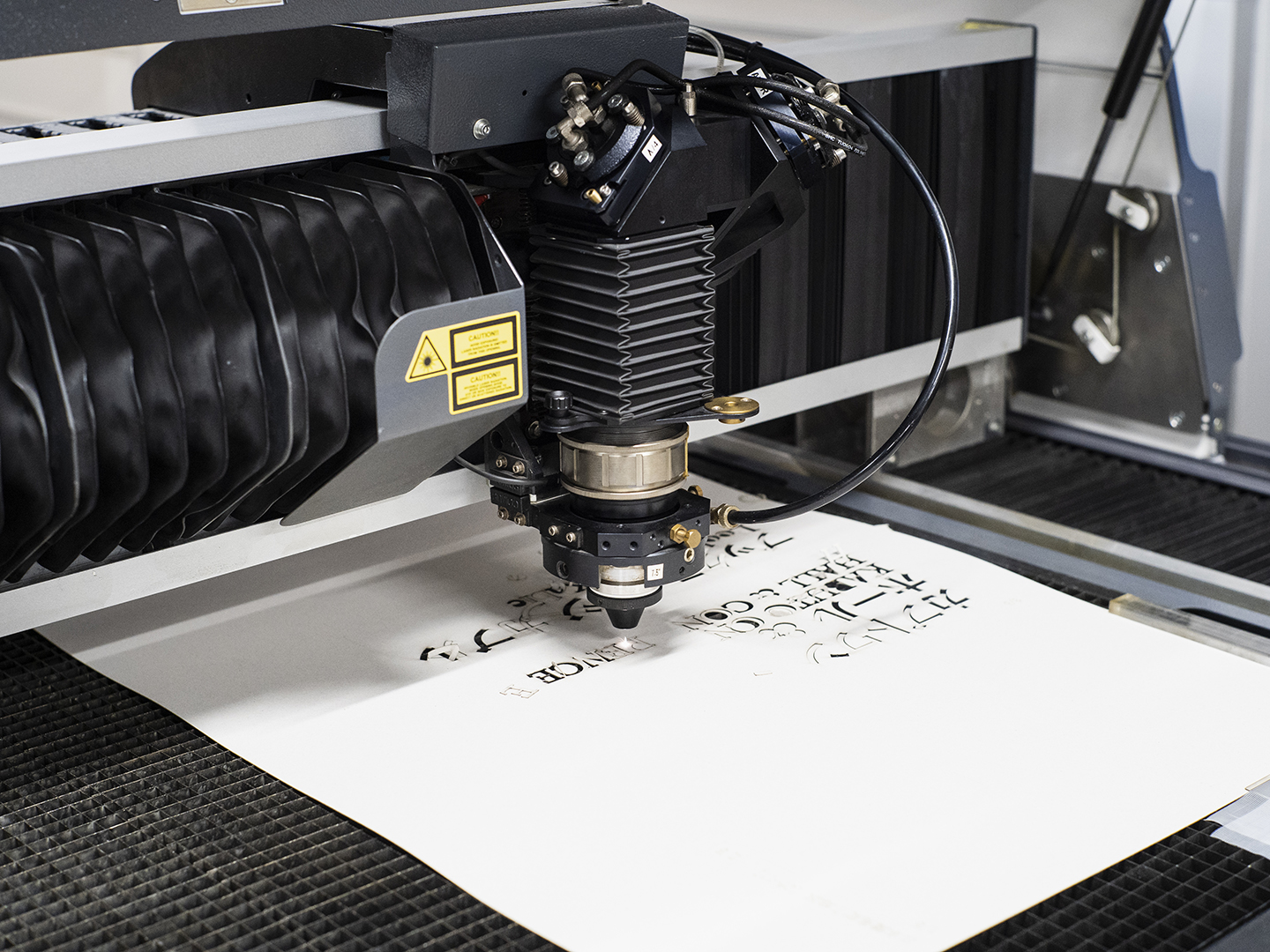

I’m getting nervous just listening to this. By the way, with the NC router and laser cutter, how are each of the machines used differently?

Narumi: It’s all about the type of material to be cut and the surface of the cut’s cross-section. For example, while both acrylic and ABS are types of plastic, we can cut acrylic with the laser, but can’t cut ABS. If we want a very clean cross-section with an acrylic piece, we will use the laser cutter.

One feature of the laser is that, because it cuts using heat, the cross-section of the cut will be vertical. Meanwhile, the NC router cuts using a rotating blade, so the state of the cut edge will depend on the angle and type of the blade. If we need a more rounded edge, we use the NC router. We also use the laser to give customers extra added service.

What do you mean by “extra added service”?

Narumi: Well, we aren’t building contractors, so the customer is the one who actually installs the sign. Usually, we ask the customer to mark the wall themselves, and then install the finished sign, but if the markings are wrong or misaligned, they won’t be able to finish anything. So, to make sure the customer doesn’t make a mistake, we give them a paper template to use when installing the sign.

The template paper is cut to match the sign using the laser, so all they have to do is put it on the wall using masking tape or something, and then put the sign together to match it, kind of like a puzzle. That way they can install the sign without having to mark each and every point. Maybe it’s because other sign makers don’t do this very often, but our customers seem to really appreciate it.

People go out of their way to choose us,

even with the spread of digital printing technology.

I think there is still demand for what we do.

I always thought that the machines would do all of the work, but people have a much bigger hand in the process than I expected.

Narumi: Yes, an there are other processes that really require the skill of a technician, too. Painting is particular tough.

It’s not like making one or two thousand of the same part in a single day; signs are a one-of-a-kind thing. We don’t use a specific color for every job – a new color has to be mixed for every single order. The customer will tell us that they want a certain color, and the person in charge will mix the paint by hand to bring it close to the color the customer is looking for.

Really? It thought you’d get specific instructions, like, use X grams of red plus Y grams of blue. That sort of thing.

Narumi: Of course, if they want to use exactly the same color used in a previous sign, we can reproduce it using our records on color mixes we have used before. But most of the time we are asked to make a color that we’ve never used before. That’s why the painting group relies on experience and intuition to create the colors through trial and error for each order.

It’s a very delicate process. Even a single drop of white can change the color drastically, so we use scales to adjust the color in increments of 0.1g. It can take as long as three days to reproduce the color ordered by the customer.

So, is painting just like the cutting process, where the approach will be different depending on the person in charge?

Narumi: No, not really. Even when you keep the color and luster the same, the thickness of the applied paint will produce subtle differences. If multiple people work on the same job, the final work will be uneven, so the manager will assign each order to a specific person, taking each employee’s individuality into account when they do so.

That’s really interesting. Unlike a factory that mass produces items, you can actually take advantage of each person’s unique skills in your work.

Narumi: What we do is use the same sorts of techniques used to paint parts for cars and motorcycles. Sometimes we try to apply car painting technologies to signs as well. But as a sign company, we have some unique facilities that regular painting companies may not have.

Our painting booth is closed off using double curtains, one of which is a blackout curtain, and when the light is turned off, it becomes pitch black inside. When we paint an LED sign, we have to place it in a dark space and turn it on to check for light leaks as we work. This kind of booth might even be a rare thing among sign makers.

Also, we are one of the very few silkscreen printers in Japan where our artisans print the silkscreens by hand on site. The number of companies that can process silkscreens on-site is falling in Japan. We also do all of our printing for walls on museums and public facilities by hand, and for fabric prints.

Is there a difference in finish between silkscreen and digital printing?

Narumi: When you print a sign from a digital design on paper, there is a minimum limit for line width, so the edges of printed characters look jagged from up close. Silkscreen lines are smooth, and where the color starts is clear and sharp. We get a lot of customers coming to us looking for a more beautiful finish. People go out of their way to choose us, even with the spread of digital printing technology. I think there is still demand for what we do.

We’ve made so many signs,

we now have a large reservoir of knowledge to draw from.

When did Omino originally start specializing in signs?

Omino, CEO : We started specializing in signs around 15 years ago. Omino started as a sign shop, and my father did everything. In the past, we did a lot of signs for supermarkets, but gradually brought in more machines and more employees. Now, whenever I walk around town, I look at every store and wonder where they had their signs made.

As a sign maker, what is the one thing that you think Omino does better than anyone else?

I think we offer higher quality products than other companies. We take great care at every step of the process, and adding manual steps ensures that quality is protected. I also think that Omino is notable in that it is one of the only sign makers using its own specialized painting technologies.

Some companies specialize in specific parts, such as paint shops or plating shops. We’re not a paint shop so we don’t accept orders that only involve painting, but our facility is more specialized than what you find at paint shops, and our technicians are very skilled. In addition, we have the knowledge needed to know how much to polish a sign to make it more beautiful, and how to cut parts to ensure a clean paint finish.

More than that, we have made a lot of signs so far, and we even have a system in place for more difficult, risky projects. I think all of this sets us apart from other companies.

When we spoke to Mr. Narumi at the start of our interview he told us that you have inquiries from people who feel that you are the company that can get difficult jobs done. How did you create a framework where you can accept orders for jobs that other companies have turned down?

Omino: I think it’s connected to experience. We’ve made a lot of mistakes, making signs where the light comes from the front of the lettering, or from the back of the lettering. And we’ve done a lot of trial and error when it comes to plating and polishing as well. We’ve made so many signs, we now have a large reservoir of knowledge to draw from.

That’s why when a customer comes to us with a difficult request, all we need to do is pick and choose the techniques we have experience in to create the new sign – it’s like creating a model airplane from a box of parts. We can figure out exactly what needs to be done to complete the job. We built up that reservoir of knowledge within our factory that we can use to meet our customers’ needs.

Another thing is how much risk a company is willing to take. When you get an order for something you’ve never done before, you definitely worry. But at the same time, there’s a lot of value to get from doing that sort of job. Whether or not you take on that challenge can have a bit effect on a company’s growth. If we feel that our toolbox of techniques includes something that can help solve the issue at hand, my hope is that more of our employees will take on that risk and enjoy the adventure.

With the current spread of COVID a lot of companies are postponing store opening right now, right?

Omino: Yes, it’s been really tough. However, that’s why I think we need to give added value to shopping in person, because we’re now in an era where you can buy anything on the internet. Being able to feel the atmosphere of a store when you visit is one way of adding value to the experience, and signs and displays are able to create that atmosphere.

The designer works hard to design the sign they want hanging on the wall, and they tell us. We hope that when customers visit their stores, they feel a bit of wonder when they see those signs.

That’s why I made the arrow signs for the video. We could have just used a marker to draw arrows on pieces of people that tell you which way to go. But isn’t it nice having something a little bit cooler? I think the power of products like that offers a better experience when shopping in real life than when shopping online.

I think the fact that we can do handwork is part of what makes us competitive

and what will keep us going.

We made the suggestion for the arrow motif for this project, but what did you think when you first heard the idea?

Omino: That’s true. That came up when we had the meeting where we talked about the purpose of signs and we decided that arrows would be good. In arrows, you get a strong sense of the fundamental role that signs play – they are there to guide people. It’s a powerful message. When you see one on a wall, people will move in the direction indicated. I thought it was a perfect fit.

If there’s something in the direction of the arrow, it acts as an indicator or waypoint. You also have this responsibility that you can’t point someone in the wrong direction, so it includes the philosophical nuance of having to do the right thing. I think it is a good signpost for the direction we would like to take in the future. I think it’s a fitting symbol for an article about a sign maker.

What are your thoughts on Omino’s future, symbolized by those arrows?

Omino: With planned stored openings decreasing and orders dropping, I think it is more important than ever to make a single product in a more technical and enthusiastic way. In recent years, customers have become more conscious of ordering from companies that can make things to exact specifications. And we are always conscious of what needs to be done to ensure that we meet customer expectations.

However, that doesn’t necessarily mean we need to increase the scale we work at by increasing the size of the factory or doubling our work force. If we doubled the number of people who work here, we might find new areas where we can’t meet our customer’s needs. In terms of scale, I think we’re already just where we need to be.

I thought that by increasing scale you would be able to increase production, but that’s not the case?

Omino: In a company like ours where we make everything to order, our employees aren’t all just doing the same work over and over. In fact, it requires flexibility. We work at a scale where the leads for each project can discuss things with each other so they can get a better idea of how to meet the customers’ needs.

That flexibility is part of the reason why we haven’t switched over to completely automated machinery. Issues in mass production can often be resolved with technology, but for a company like ours, where we are making products in extremely small lots, in many cases it can be faster to do things by hand than to leave it to the machinery.

That’s why I want us to continue to make the best use of manual work. I think the fact that we can do handwork is part of what makes us competitive and what will keep us going. I would like us to keep taking the initiative in creating unique products that are only possible because we add the human touch.

FACTORY

omino co.,ltd.

omino co.,ltd.

Sign maker founded in 1975. Headquarters located in Tokyo’s Sumida Ward, factory located in Yashio, Saitama Prefecture. Makes signs using ABS, acrylic, and other resins, and metals like stainless steel, aluminum, and brass, in addition to LED signs and silkscreen printed signs. Also handles digitally processed items using large-scale laser cutter and 3D machining routers.

Yashio Factory: 496-1 Nichome, Yashio, Saitama Prefecture

STAFF

who made this

Nozomi Takagi

Writer

Born in 1992. Writer and editor based in Tokyo covering various fields including music, art, business, and science.Articles appear primarily in Time Out Tokyo, Qetic, News Picks, and more. On organizing team of Gampeki Music Festival.