INDUSTRIAL JP

idstr.jp open shareOctober 23, 2016

AT-4

sakamoto factory

interview

Beyond creating, it’s fun when it sells. Working within a connected society.

// sakamoto factory / interview

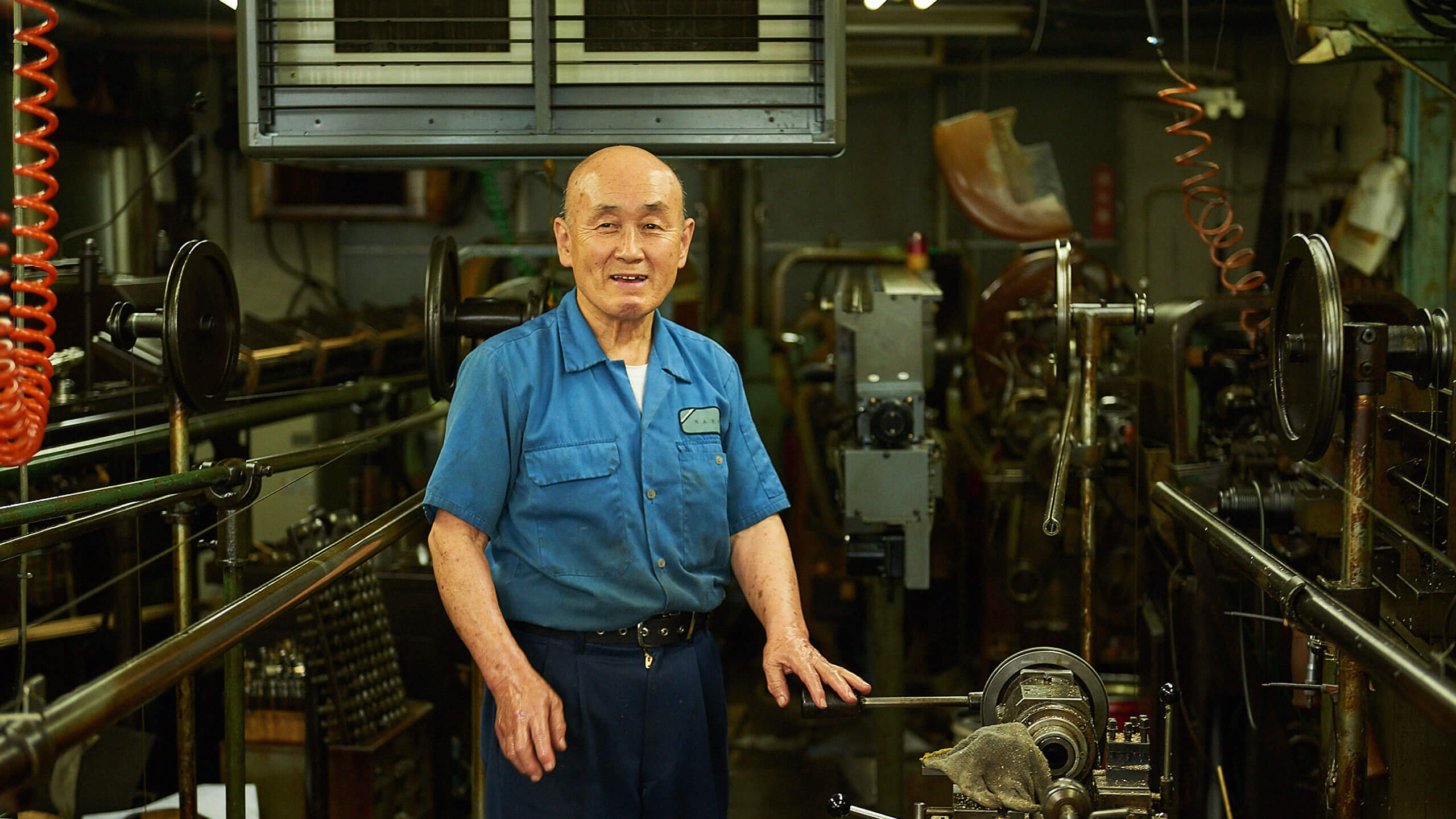

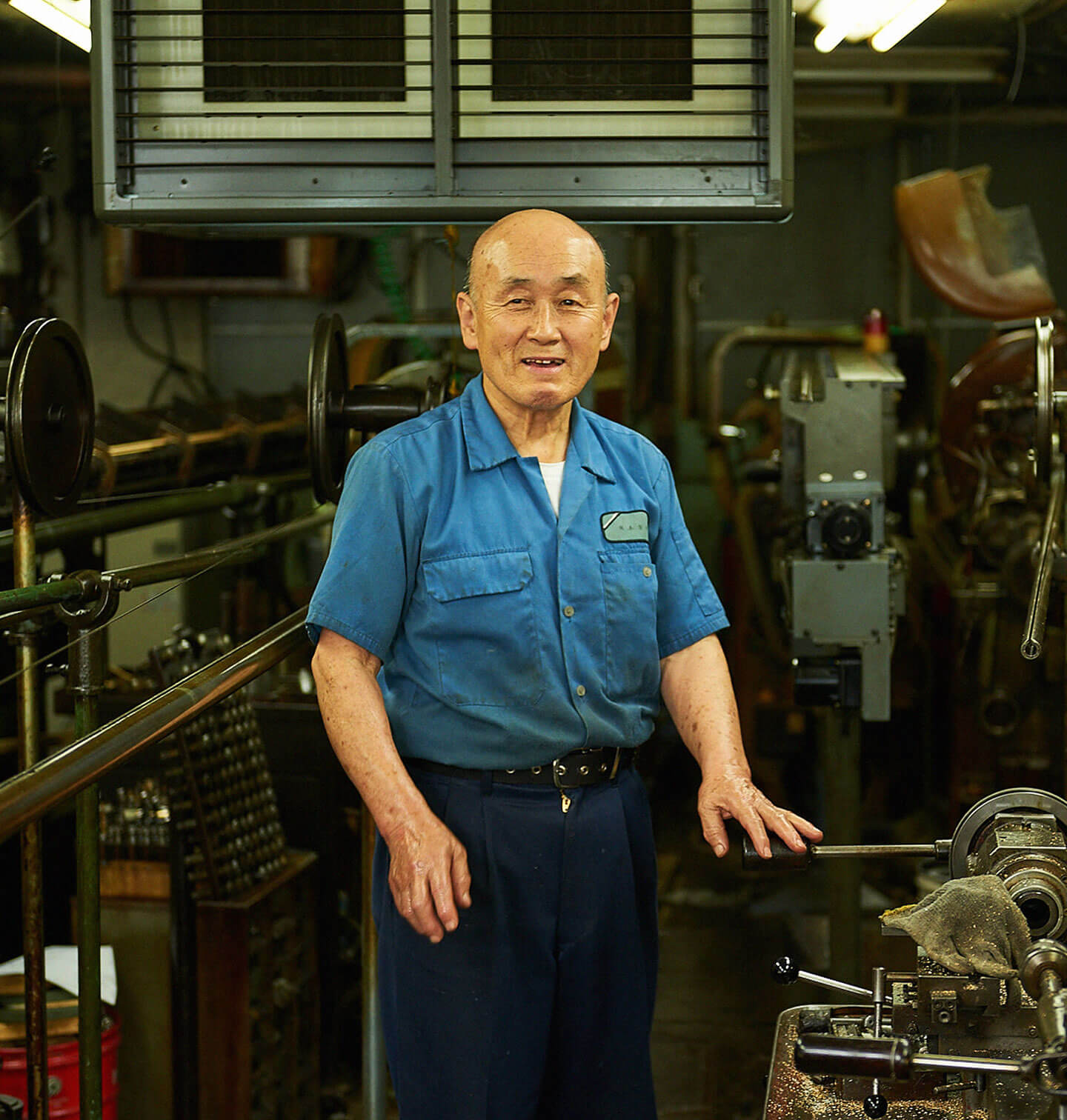

Sakamoto Factory can be found right by Fudomae Station in the Shinagawa Ward. They manufacture metal parts called inserts that may sound unfamiliar to many of us. The track by Cherryboy Function was inspired by sounds from their factory. We had the pleasure to speak to the head of the factory who is still active despite being in his 70’s.

sakamoto metal

ID-4

sakamoto factory

cherryboy function

It’s also used for switch boxes in meter-like instruments. Since they’re hidden away like this, it might be hard for people to imagine.

So you manufacture inserts at Sakamoto Factory. What exactly are these inserts?

They’re parts embedded in plastic moldings, but it’s a little hard to explain. It’s essentially a part that receives the screw.

How are these parts used?

This is an instrument device. Inside this meter-like instrument, there’s a switch box which is tightened by these inserts. Since they’re hidden away like this, it might be hard for people to imagine.

I see, it might be difficult to notice unless you’re actually looking at it that carefully. How do you manufacture these?

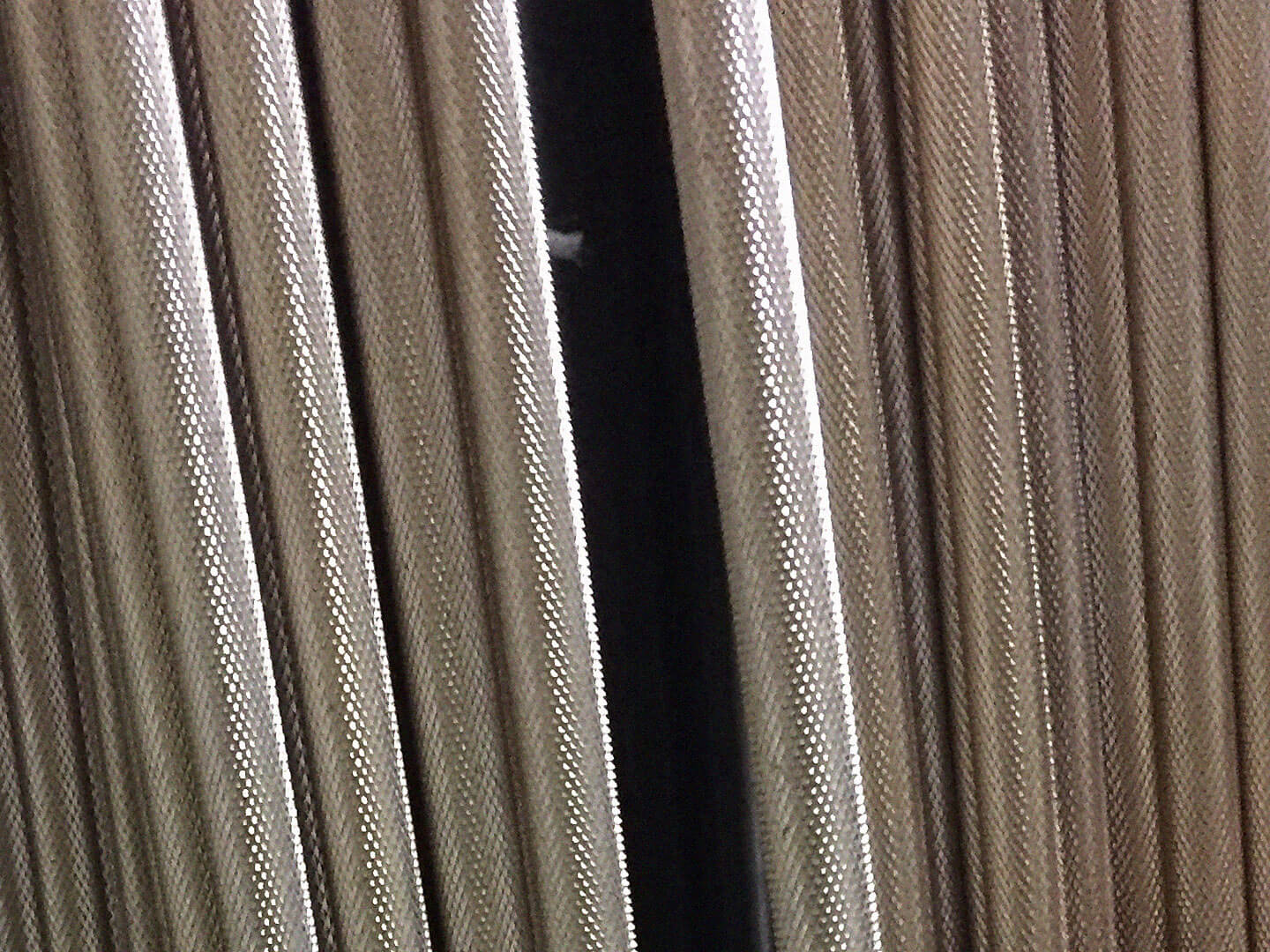

We take a long cylindrical material and process this in a machine. We manufacture this by slicing up the material, opening up a hole on the cross section then sharpening them.

Do you do anything special when making inserts?

We change up the order in which the blades are used, affecting where the insert’s edges are placed. When we design the processing order, we calculate backwards from the envisioned finished product. How these blades are used to process the materials is decided by humans. That’s where we put in a lot of care. When we receive orders, these processing steps are not included in the drawing.

So the bit before operating the machines is important.

It’s not like you put it into a machine and everything is automatically done. This may be why young people these days are even more discouraged from getting involved (laughs).

But it must be fun because you have to think for yourself?

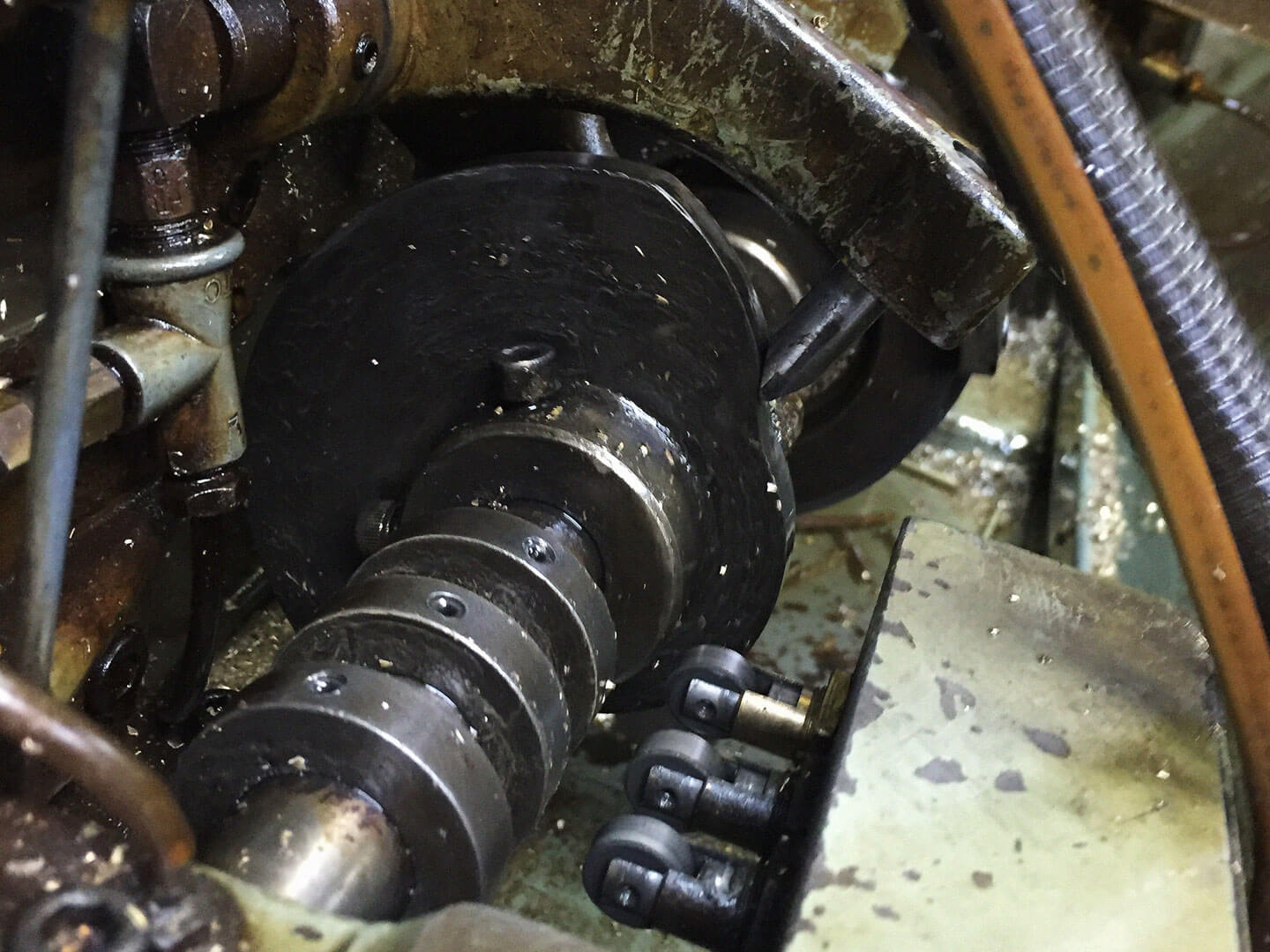

That all depends on the person. Curious people will passionately ask questions about how they’re made. They manufacture the shape of the controlling parts themselves, decide on the order the blades are used to build something that fits the shape of the final product. These controlling parts are called cams, and you have to make these yourself too. You have to calculate the necessary movements, draw up a blueprint, and process a metal plate to make these. Then finally, attach it onto this machine.

You could say that it’s by eye, but of course it’s also based on calculations (laughs).

How do you process these cams?

You see how there are curved lines on these plates? Guided by these markings, we calculate how the machine movements are affected by how much we carve off. I’ve got the feel for this all in my head. You open up a hole into the metal plate, and carve to make a basic shape around the hole. Then you put it through the grinder to smooth it out.

Do you mean you measure all of this by eye?

You could say that it’s by eye, but of course it’s also based on calculations (laughs). For example, ‘for this product, we have to create spiral carvings every 1mm, shifting the cam by 20 degrees to move the arm of the machine.’ Something like that.

So there are standards based on numbers, but also an element of intuition?

That’s what’s great about being a craftsperson, but also what’s not. People say “what’s the point of taking such an analog approach?” which is a valid question. But to manufacture in higher volume taking an analog approach is better suited. Even for a simply designed product, when it’s digitally controlled machines cannot produce in larger lots. Besides, the cost jumps up by five or ten times more. On the other hand, analog machines can produce in larger lots. So there’s an essential demand for machines like these. Even when carving at an accuracy of 1-2mm, we use these analog machines. We take various types of blades, thinking about which ones to use and how to sharpen them. All based on our own thinking.

Do you sharpen the blades yourself? These blades that are attached on these machines - did you personally process these as well?

That’s right. There’s never a time when the perfect blade is conveniently sold in other places. So we buy these plain blades, put it through a grinder and create the right shape. Only a craftsperson can do this. Also, the blades wear out as they’re used over time, chipping or becoming blunt. It’s all handmade, which means it affects accuracy and the measurement of the blade itself.

For the layperson, it’s difficult to even sharpen kitchen knives. We can see how only a craftsperson can manage to create these precise parts according to the blueprint. How do you know when to maintain your tools?

Just by the way it looks. We can’t be monitoring it constantly, so for one entire material used, we check on it about once or twice. We check to see if the parts are made well. If they’re not, that means the ones made before and after aren’t either. But analog machines are still faster and more efficient, and more cost effective.

How long does it take to be able to do what you do?

It depends on whether you like the job or not, but it’ll take at least 5 to 6 years. People who like it will be fast learners. If you don’t, you can spend 20 years and still be disappointing.

I guess that applies to other professional genres too.

Precision is achieved not by the precision of the machineries, but by the precision of the craftsperson operating it.

Are there examples where these inserts are used for products that are familiar to us?

Like these volume knobs. There are fewer and fewer places where you can manufacture these, mainly due to how difficult it is to process aluminum. We press-fit resin inside, insert a brass shaft, stop it with side screws, and add grooves on the side, one by one. We apply a ’pear skin’ satin finish on the surface, applying sand grains to matte it out. Instead of letting the aluminum shine, we create a muffled texture. You know how the stereos and amps of Japanese audio makers have large knobs? That’s quite a find nowadays. Audio makers should be in a bit of a struggle by next year or the following. Japanese factories that can manufacture these are decreasing in number and hard to come by.

Can these be made overseas?

Well, the audio makers prefer to build these domestically, you see. One reason is that they only make about 1,000 - 2,000 products. If you’re producing a few hundred thousand of these, you might take it overseas, but not when the product is a discretionary or luxury item. Although it isn’t impossible to ask an overseas factory.

So overseas factories are that cheap?

Yes, we can’t compete on price. But even if an overseas factory used the same machines to make the same product, the quality and precision is different. Precision is achieved not by the precision of the machinery, but by the precision of the craftsperson operating it. When Japanese craftspeople operate these analog machineries, the precision is just amazing. Based on our clients’ product standards, we are only allowed a margin of error of a few millimeters. Overseas, you can’t achieve this kind of precision with analog machines. Having said this, you can with certain digital machines these days. Just slot in the material and enter some numbers. Also, some factories overseas are really stepping up their game, especially Taiwan. In Japan, we’re seeing fewer and fewer factories that deal with these tougher materials. Maybe we’ll see an increased number of places dealing with softer materials.

What are some of these softer materials?

Plastic. We manufacture more in recent years too. But processing isn’t so easy. There’s a rate of contraction that occurs by the friction heat created through the carving process. Metal materials are easier to deal with so we didn’t used to deal so much in plastic, but we’re taking it up as a new challenge. One reason for this is that we can set our own price for smaller lots for plastic, from 100 to 1,000 lots.

If there’s anything we can’t do at our factory, we’ll get another factory involved. Sometimes it does feel like we’re creating with everyone in neighborhood.

It must be tough having to learn to deal with new materials.

Not really. We just need to get some advice on the know-how. When we visit a factory specializing in plastic, we have some friends there too. Factories around these areas all coordinate and help each other out. For example, if you run out of parts you might go and borrow some. If you need some materials, go pick some up.

Kind of like an old custom in Japan borrowing soy sauce from your neighbors?

Yeah, just like that. When we need only a little bit of mill ends, if you buy the whole lot it’ll be too huge. Most people work in a 4 - 5 people team, so we stay accommodating among our factory friends. We’ve even given away parts for free. We don’t just accommodate for materials, but in relation to our jobs too. If there’s anything we can’t do at our factory, we’ll get another factory involved. Sometimes it does feel like we’re creating with everyone in neighborhood.

When you think about it that way, it’s nice having people around who you can think and work with.

Well, I’ve been here for a few decades. If I move out I doubt that it’ll work the same. Just like a convenience store, products sell for particular price because of the location. When you’re in Hachioji or Saitama, prices go down significantly. When you go out of town there are quite a few factories around. When you ask their price, they’re very affordable.

Why do prices change when you’re in the same Kanto area?

Because they make in larger lots, but when you’re in Tokyo, you would want to pursue a different path. You know how you can sell things a little more expensive at a convenience store? It offers a variety of things that are readily available. It sells quickly.

So we understand convenience is a factor. You’re also older in age compared to the others. Do people rely on you often?

I’m in my 70’s. The rest are in their 40’s, 50’s and 60’s so it varies, but age really doesn’t make a difference. Actually, quite often I learn a lot from the others. There are those who are knowledgeable despite their younger age, so I go and ask them. Things like, what happens to the blade when the material is different. What kind of oil they use.

They may not be so young, but do younger people also use analog manufacturing machines?

The second generation factory owner doesn’t. The numerically controlled machines are easy because you just need to attach the blades, but he can’t use the analog machines. We’re actually a little worried about this - after his father retires. There are things you can only make on analog machines. On the other hand, I can’t operate the numerically controlled machines, so I leave it to my younger colleagues. They taught me how to use it once, but after not operating it for six months, I had totally forgotten (laughs).

These days, you need to be 60% a craftsperson, and 40% a salesperson. People back in the day couldn’t seem to do this.

When you see products made by other factories and compare them to yours, can you tell the difference?

I can tell most things that we’ve made here. Even when they’re the same product. The touch, and cross sections are different. Also the way the holes and slices are made, it’s subtle but they’re different. We all have our own individual styles and it comes out subconsciously. Ordinary people probably can’t tell the difference, but we can. You can ask anyone from a factory and they’ll tell you the same. There are slight differences in measurements too. We can tell these apart because we’ve been looking at these for decades. Anyone who’s been making the same thing for 40 or 50 years should be able to do the same. Some people do seem surprised to learn that we’ve been making the same thing for decades without getting sick of it.

But that’s what craftspeople do, isn’t it? Dedicate their craft for a singular cause.

As for us, we try not to get too focused. We settle where it feels well-made and right. There’s no point if we get too involved and the profit doesn’t increase in correlation. I guess we’re craftspeople, and simultaneously merchants.

There’s an artist in the music industry who said “the deadlines make the work”. It’s completed because you say “it’s done”. Hearing you talk about settling at a certain point made me think that maybe you’re talking about the same thing. Because there’s a deadline, because you decide it’s complete, the product is finalized.

That’s right, there are differences in how people say it, and it’s hard to pinpoint the right expression. But just as a feeling, there are times when you feel “now, that’s done”. Of course, there are people who take it to the very end. These days, you need to be 60% a craftsperson, and 40% a salesperson. People back in the day couldn’t seem to do this. You need that 30 or 40% doing sales so you can support your life, but most people couldn’t shake off their craftsperson disposition and ended up poor. Those people hit their limits, and end up quitting. Even craftspeople can’t just create things, if we want to eat, we have to sell. In other words, you can win an award with your technique and skills, but you can’t eat with that award - you have to be able to sell the products. And to know how to present the products in an attractive way, you need to think in another way and use ideas. For example, the trial and errors of humans hoping to take it easy, can help us come up with a way to shorten a 3-step production process to a single one.

That sounds like quite an adventure. There must be times when things don’t go quite as planned.

Of course there are. For example, ending up ruining all the blades you just put to use. But you need trials and errors like that to think about the next steps. It’s great when things go well, but you have to think about how much you can profit from that. Nothing happens if you just create. It’s fun when it sells. It’s about connecting with customers, and working within the society.

FACTORY

sakamoto factory

SAKAMOTO FACTORY LTD.

Sakamoto Factory is in the Gotanda area of Tokyo. It’s main focus is on metallic inserts used in plastic molding and other products most of us don’t notice. Most of their manufacturing process is still analog. Much of their work is custom-made, and available in different sizes. They are able to accommodate sudden and same-day orders. Their metal parts are made of BSBS, iron, stainless steel, aluminum, and resin.

5-15-9 Nishigotanda, Shinagawa-ku, Tokyo 1410031 Japan